What Veterinary Autoclave is right for me?

There is a wide range of options available, but which kind of autoclave should you go for? It really depends on your own requirements the below should hopefully clear up which options are better for you.

Chamber Size

Our veterinary range of (steam injection) autoclaves is available in 3 sizes. Starting at 18 litres this provides a suitable space for the majority of first opinion practices. Our 23-liter autoclave offers a larger capacity in a similar footprint. The longer chamber does mean longer tools can fit inside, perfect for orthopaedic kits and longer instruments such as the emasculators used by farm practices. Our 60 Litre model offers plenty of capacity for very busy practices and referral hospitals, allowing for large batches of instruments to be serviced at the same time.

Vacuum or non-Vacuum

We would always recommend using a vacuum autoclave for instrument processing in animal health. Non-vacuum autoclaves are only suitable for the sterilization of non-wrapped solid loads and offer very limited load drying.

Dentalex stock both the Midmark VetAssure ‘B’ and ‘S’ class vacuum autoclaves. The ‘B’ class with its fractionated vacuum will offer the best air removal, steam penetration and load sterility. Both models incorporate a vacuum for better load drying performance.

‘B’ class offer future proofing allowing for full porous loads & narrow lumen equipment to be sterilized. S Class units still cover a good range of load types if your instruments are of a simpler nature.

Load types

| Load type | VetAssure “S” Class | VetAssure “B” Class |

| Solid load | √ | √ |

| Small porous objects | √ | √ |

| Small sized porous loads | √ | √ |

| Full porous load | √ | |

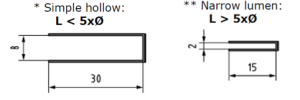

| Simple hollow load (ex Type B) * | √ | √ |

| Narrow lumen (ex Type A) ** | √ |

(Newmed)

Do I need a water system?

A separate water filtration system can save your practice a lot of time and money, as well as reducing manual handling.

There are a few methods available for creating water at your practice.

Our preferred method of providing purified water for sterilization is through a commercial deionization resin vessel.

Water passes through the resin and all impurities are removed, a sediment and hollow fibre filter then removes any particulates and bacterial load from the water, creating clean and pure water.

Impurities are removed from the water as it passes though the resin within the deionization vessel. An additional sediment and hollow fibre filter ensure that any particles and bacterial load are removed from the water, creating clean and pure water.

The purifying of tap water is usually the quickest, most economic, and environmentally friendly method as this reduces single use plastic as well as not needing to be delivered.